Professional Manufacturer Of High-end Wire And Cable Equipment

Professional Manufacturer Of High-end Wire And Cable Equipment

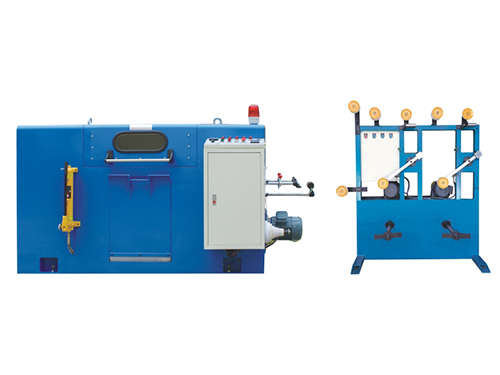

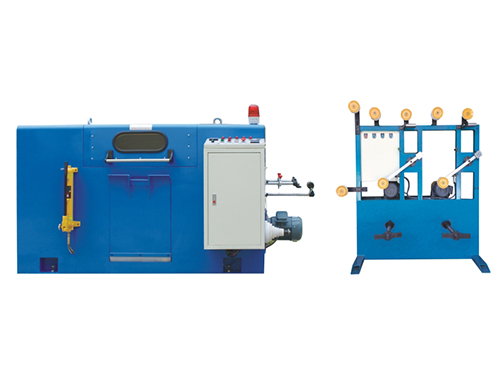

Twisting machine is also known as high-speed stranding machine, stranding machine, and staking machine.

The stranding machine is widely used in the stranding of various soft/hard conductors (copper wire, enameled wire, tinned wire, copper clad steel, copper clad aluminum, etc.) and electronic wires, such as power cords, telephone wires, Audio cable, video cable, car cable, network cable, etc. Twist multiple single-branch conductors into one strand to meet the requirements of wire technology.

Technical features:

1. The maximum speed of the main shaft of the stranding machine is 3000rpm.

2. Automatic tension control: When twisting the wire, the tension of the winding wire needs to be continuously increased when the full winding is received from the bottom of the plate. This machine can automatically track and adjust the winding tension; make the entire winding tension uniform, and at the same time The machine can also adjust the tension without stopping the machine.

3. The main engine is lubricated by engine oil and cooled by natural circulation, which effectively prolongs the service life of the spindle bearing.

The thread passing system adopts a new structure. The wire passes directly from the main shaft guide wheel to the bow belt, minus the scratches and jumps caused by the failure of the corner guide wheel on the aluminum plate.

4. There are three compression devices in the machine to ensure the roundness of the conductors after stranding and reduce the loss of insulating materials.

5. The whole machine adopts synchronous belt transmission, and there is no lubrication point inside the machine, which keeps the machine clean, and the stranded wire is free of greasy dirt. It is suitable for conductor stranding of various wire types with high surface cleanliness requirements.

6. To adjust the twisting distance, only need to replace a take-up wheel, and adjust the twisting direction only to turn the reversing rod, which is simple and convenient to operate, thereby reducing the error rate and work intensity of the operator. The bearings of the whole machine are made of well-known Japanese brands, and the bow straps are made of new materials, which are flexible, and avoid jumps caused by vibration during high-speed operation. The frequency converter, PLC, magnetic powder clutch, electromagnetic brake, hydraulic jack, etc. are all imported well-known brands , Reduce failure rate and maintenance cost.

About

Introduction Plant Exhibition Customer CertificateProduct

Silicone Equipment Series Wire And Cable Extrusion Machine Series Silicone Extruder Series High-speed Stranding Machine Series More Products WeChat

WeChat