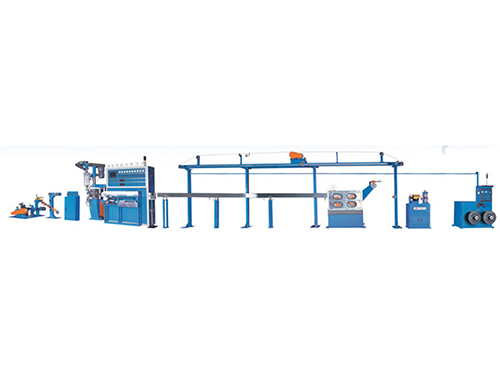

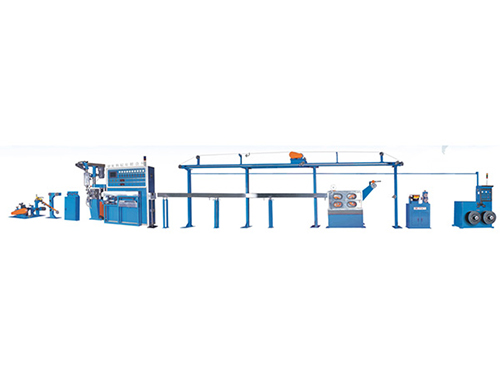

Professional Manufacturer Of High-end Wire And Cable Equipment

Professional Manufacturer Of High-end Wire And Cable Equipment

General plastic machinery is generally divided into two types, extrusion machine is one of them, and the other is injection molding machine. The extruder is to extrude the molten plastic through a fixed-shaped extruder under the action of a screw, and is cut after being shaped by water cooling under the action of a tractor. It is mainly used for mass continuous production of various products with the same cross-section, such as pipe rods, profiled materials, etc. It can also be used for plastic modification and granulation. The injection molding machine injects molten plastic into the mold and becomes the product after cooling. It has a wide range of uses. Depending on the plastic, the place of use is also different. The host of the plastic extruder is an extruder. It consists of a pressing system, a transmission system and a heating and cooling system.

1. Compression system. The compression system includes screw, barrel, hopper, head, and mold. The plastic is plasticized into a uniform melt through the compression system. The screw continuously extrudes the machine head.

(1) Screw: It is the most important part of the extruder. It is directly related to the application range and productivity of the extruder. It is made of high-strength, corrosion-resistant alloy steel.

(2) Cylinder: It is a metal cylinder, generally made of alloy steel or composite steel pipe lined with alloy steel that is heat-resistant, high-pressure-resistant, strong, wear-resistant, and corrosion-resistant. The barrel and the screw are matched to realize the crushing, softening, melting, plasticizing, exhaust and compaction of the plastic, and the continuous and uniform delivery of the rubber material to the molding system. Generally, the length of the barrel is 15-30 times its diameter, so that the plastic can be fully heated and plasticized as a principle.

(3) Hopper: The bottom of the hopper is equipped with a cutting device to adjust and cut off the material flow. The side of the hopper is equipped with a sight hole and a calibration metering device.

(4) Machine head and mold: The machine head is composed of an alloy steel inner sleeve and a carbon steel outer sleeve, and a forming mold is installed in the machine head. The function of the machine head is to transform the rotating plastic melt into parallel linear motion, uniformly and smoothly introduce it into the mold sleeve, and give the plastic the necessary molding pressure. The plastic is plasticized and compacted in the barrel, and flows into the molding die of the die through the neck of the die through the porous filter plate along a certain flow path. The die core and die sleeve are properly matched to form an annular gap with a decreasing cross-section, so that the plastic melt is in A continuous and dense tubular coating is formed around the core wire. In order to ensure that the plastic flow path in the machine head is reasonable and eliminate the dead corner of the accumulated plastic, a shunt sleeve is often installed. In order to eliminate the pressure fluctuation when the plastic is extruded, a pressure equalizing ring is also installed. The machine head is also equipped with a mold correction and adjustment device, which is convenient to adjust and correct the concentricity of the mold core and the mold sleeve. According to the angle between the material flow direction of the die head and the center line of the screw, the extruder divides the die head into an oblique die head (with an angle of 120°) and a right angle die head. The shell of the machine head is fixed on the fuselage with bolts. The mold in the machine head has a mold core seat, and is fixed to the inlet port of the machine head with a nut. The mold core seat is equipped with a mold core, a mold core and a mold core seat. There is a hole in the center of the core for passing the core wire; a pressure equalizing ring is installed in the front of the machine head to equalize the pressure; the squeeze molding part is composed of a mold sleeve seat and a mold sleeve, and the position of the mold sleeve can be adjusted by the bolt through the support , In order to adjust the relative position of the mold sleeve to the mold core, it is convenient to adjust the uniformity of the thickness of the cladding layer. The outside of the machine head is equipped with a heating device and a temperature measuring device.

2. Transmission system The function of the transmission system is to drive the screw and supply the torque and speed required by the screw in the extrusion process. It is usually composed of a motor, a reducer and a bearing. 3. Heating and cooling device Heating and cooling are necessary conditions for the plastic extrusion process to be carried out.

(1) Nowadays, the extruder usually uses electric heating, which is divided into resistance heating and induction heating. The heating sheet is installed in the body, neck, and head of each part. The heating device externally heats the plastic in the cylinder to heat it up to reach the temperature required for the process operation.

(2) The cooling device is set up to ensure that the plastic is in the temperature range required by the process. Specifically, it is to eliminate the excess heat generated by the shear friction of the screw rotation, so as to prevent the plastic from decomposing, scorching or shaping difficult due to excessive temperature. The barrel cooling is divided into two types: water cooling and air cooling. Generally, air cooling is more suitable for small and medium-sized extrusion presses, and water cooling or a combination of the two types of cooling are mostly used for large-scale extrusion presses; screw cooling mainly uses central water cooling to increase the solid conveying rate of materials , Stabilize the amount of glue and improve the quality of the product. However, the cooling at the hopper is to strengthen the conveying effect of solid materials and prevent the plastic particles from sticking and clogging the material opening due to heating, and to ensure the normal operation of the transmission part.

Precautions for using the extruder:

1. The extruder should run forward to avoid reverse rotation.

2. Do not run on an empty stomach. You must run the machine with heating, so as to avoid sticking (shaft holding).

3. It is strictly forbidden to enter ironware and other miscellaneous items in the feed port and vent hole of the extruder to avoid accidents and affect production.

4. Safe use of electricity and grounding wire.

5. When the machine is running, it is forbidden to touch the rotating parts such as the feeding port, the discharging port, the belt, the gear, etc. by hand.

6. Lubricant should be injected into the machine before use to avoid damage to the machine. Plastic extruder as one of the three major synthetic materials has developed rapidly since its inception. Plastics to replace steel, plastics to replace non-ferrous metals, plastics to replace cement, etc., are widely used in agriculture, building materials, packaging, machinery, electronics, automobiles, home appliances, petrochemicals and national defense, extrusion machines, and people’s daily lives . Therefore, it can be predicted that in the 21st century, plastics will be one of the most important raw materials for human activities. Extrusion machine design Since extrusion molding is the most important form of plastic processing, it is of great significance to develop plastic extrusion molding technology and equipment. Internationally, there are three main types of new mixing equipment used for the blending and modification of polymer materials: co-rotating parallel twin-screw extruders, reciprocating screw mixers and tandem disc extruders. Among them, the small co-rotating parallel twin-screw extruder can be produced in China, and the extruder technology but the 10,000-ton level large-scale mixing press and granulation unit all rely on imports. at the same time. Reciprocating screw kneader and tandem disc extruder are necessary devices for the preparation of high filling and high value-added polymer alloys. At present, the development of them in China is just in the prototype stage. The specifications are not many, the varieties are not complete, and they have a wide range of Prospects.

About

Introduction Plant Exhibition Customer CertificateProduct

Silicone Equipment Series Wire And Cable Extrusion Machine Series Silicone Extruder Series High-speed Stranding Machine Series More Products WeChat

WeChat