Professional Manufacturer Of High-end Wire And Cable Equipment

Professional Manufacturer Of High-end Wire And Cable Equipment

产品分类Product Categories

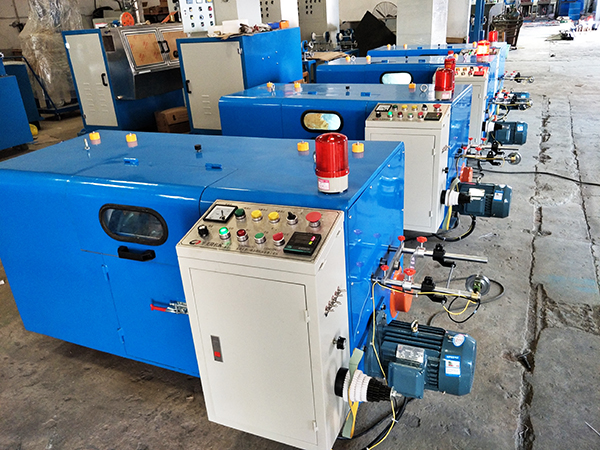

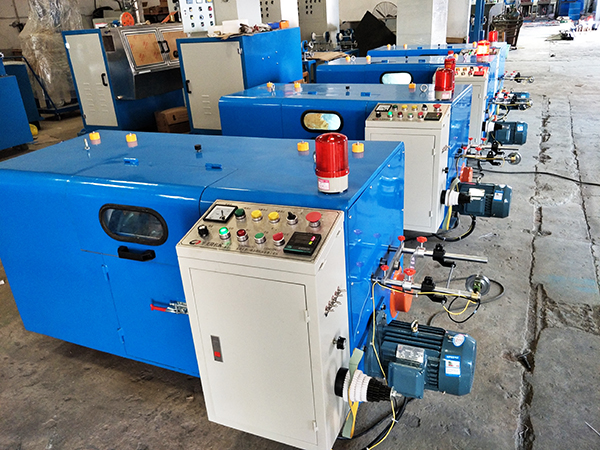

Our factory is a professional manufacturer of high-speed stranding (bundling) machines in the industry. After years of development and production, it has now formed a full range of mature models to meet the different specialized needs of various customers. This series of models has exquisite design and craftsmanship. Mature, reasonable structure, stable operation, high quality, energy saving and high efficiency, well received by various customers, can be widely used in various soft/hard conductor wires (copper wire, enameled wire, tinned wire, copper clad steel, copper clad aluminum, etc.) ) And twisting of electronic wires, such as: power cords, telephone lines, audio cables, video cables, car cables, network cables, etc.

Technique Feature1. The maximum speed of the spindle is 4500rpm.

2. Automatic tension control: When twisting the wire, the tension of the take-up must be continuously increased when the full reel is received from the bottom of the reel. The machine can automatically track and adjust the take-up tension; make the tension of the entire reel uniform, and the machine also The tension can be adjusted without stopping the machine.

3. The main engine is lubricated by oil and cooled by natural circulation, which effectively prolongs the service life of the spindle bearing. The thread passing system adopts a new structure, the wire passes directly from the main shaft guide wheel to the bow belt, minus the scratches and jumps caused by the failure of the corner guide wheel on the aluminum plate.

4. There are three compression devices in the machine to ensure the roundness of the conductor after twisting and reduce the loss of insulating materials.

5. The whole machine adopts synchronous belt transmission, there is no lubrication point inside the machine, and the inside of the machine is kept clean, and the stranded wire is free of oil stains. It is suitable for the stranding of conductors of various wire types with high surface cleanliness requirements.

6. To adjust the twisting distance, only need to replace a take-up wheel, and adjust the twisting direction only to turn the reversing rod, which is simple and convenient to operate, thereby reducing the error rate and work intensity of the operator. ·The bearings of the whole machine are made of well-known Japanese brands, and the bow straps are made of new materials, which are flexible, and avoid jumps caused by vibration during high-speed operation. The frequency converter, PLC, magnetic powder clutch, electromagnetic brake, hydraulic jack, etc. are all imported well-known Brand, reduce failure rate and maintenance cost.

| Specification model | HML-300P |

| use | Suitable for stranding of bare stranded wire, tinned wire, copper clad aluminum, enameled wire, alloy wire, etc. |

| Swing speed | 4500r/min |

| Give the wire diameter | φ0.025-φ0.12mm |

| Stranded cross-sectional area | 0.005-0.08mm |

| Lay length | 0.8~10.6mm 14part |

| Take-up shaft | φ200mm×134mm×30mm(Made according to your company's drawings), using manual pump hydraulic lifting |

| Drive motor | 3HP motor plus inverter |

| Area of refusal to pay | 1900×750×950 |

| Twist | S/Z reversing can be selected arbitrarily, when adjusting the twisting direction, you only need to pull the reversing lever at the arranging device by hand, and the operation is simple |

| Cable | Bearing type cable, row spoke and row pitch can be adjusted |

| brake | Use electromagnetic brake, internal and external disconnection, automatic braking when the meter reaches the meter |

| Tension control | The magnetic powder clutch controls the winding tension, and the PLC program controller automatically follows the heald to adjust the tension, and the tension is constant |

About

Introduction Plant Exhibition Customer CertificateProduct

Silicone Equipment Series Wire And Cable Extrusion Machine Series Silicone Extruder Series High-speed Stranding Machine Series More Products WeChat

WeChat