Professional Manufacturer Of High-end Wire And Cable Equipment

Professional Manufacturer Of High-end Wire And Cable Equipment

When making different plastic products, the operating points of the extruder are different, but there are also similarities. The following briefly introduces the same operating steps when extruding various products and the operating points of the extruder that should be paid attention to.

1. Preparations before driving.

(1) Plastics used for extrusion molding. The raw materials should meet the required drying requirements, and further drying should be done if necessary. The raw materials are sieved to remove agglomerates and mechanical impurities.

(2) Check whether the water, electricity, and gas systems in the equipment are normal, to ensure that the water and gas paths are unblocked and leak-free, whether the electrical system is normal, whether the heating system, temperature control, and various instruments work reliably; the auxiliary machine is empty Run the car at low speed to observe whether the equipment is operating normally; start the vacuum pump of the sizing table to observe whether it works normally; add oil and lubricate the lubricating parts of various equipment. If any fault is found, remove it in time.

(3) Install the head and sizing sleeve. According to the variety and size of the product, select the specifications of the machine head. Install the machine head in the following order.

2, drive

(1) You can start driving after the constant temperature. Before driving, you should tighten the head and the flange bolts of the extruder again to eliminate the difference in thermal expansion between the bolts and the head. The order of tightening the head bolts is diagonally. , The force should be even. When tightening the flange nuts of the machine head, the tightness of all sides must be consistent, otherwise the material will run out.

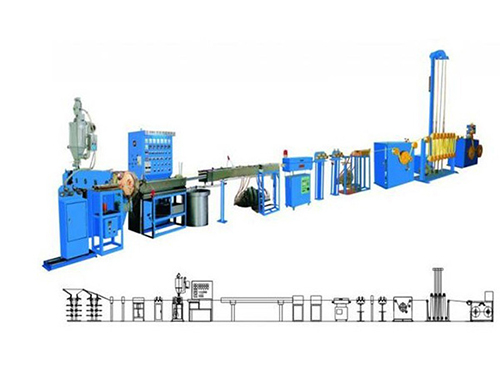

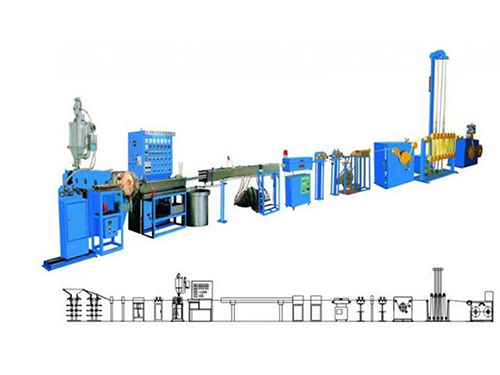

(2) When driving, first press the "ready to start" button, then connect the "start" button, and then slowly rotate the screw speed adjustment knob, the screw speed starts slowly. Then gradually speed up, while adding a small amount of material. Pay close attention to the indication changes of the host ammeter and various indicator heads when feeding. The screw torque cannot exceed the red mark (generally 65% to 75% torque). Before the plastic profile is extruded, no one is allowed to stand directly in front of the die, to prevent injury accidents caused by bolts breaking or due to damp and foaming raw materials. After the plastic is extruded from the die of the machine head, the extrudate needs to be slowly cooled and led to the traction device and the shaping die, and these devices are activated. Then according to the indication value of the control instrument (see the figure below) and the requirements for extruded products. Adjust each part accordingly to make the entire extrusion operation reach a normal state. And add enough material as needed, the twin-screw extruder uses a metering feeder to feed evenly and at a constant rate.

(3) Generally, it can be judged according to the appearance of the extruded material, that is, the surface is shiny, free of impurities, no foaming, burnt material and discoloration. The extruded material is squeezed to a certain extent without burrs or cracks. , There is a certain degree of flexibility, which means that the material is plasticized well. If the plasticization is poor, the screw speed, barrel and head temperature can be adjusted appropriately until the requirements are met.

(4) During the extrusion production process, check whether various process parameters are normal according to the process requirements and fill in the process record sheet. Check the quality of the profile products according to the quality inspection standards, and take timely solutions when problems are found.

3, parking

(1) Stop feeding, squeeze out the plastic in the extruder, and when the screw is exposed, turn off the power of the barrel and head, and stop heating.

(2) Turn off the power supply of the extruder and auxiliary machines, and stop the screw and auxiliary machines.

(3) Open the connecting flange of the machine head and remove the machine head. Clean the perforated plate and various parts of the machine head. In order to prevent damage to the inner surface of the machine head during cleaning, the residual material in the machine head should be cleaned with steel laws and steel sheets, and then the plastic adhering to the machine head should be removed with sandpaper, polished, and coated with engine oil or silicone oil. rust.

(4) Clean up the screw and barrel. After removing the head, restart the main engine, add parking material (or crushed material), and clean the screw and barrel. At this time, the screw should be selected at a low speed (about sr/min) Reduce wear. After the stopped material is crushed into powder and completely extruded, compressed air can be used to repeatedly blow out the remaining pellets and powder from the feeding port and the exhaust port until there is no residual material in the barrel, then reduce the screw speed to zero and stop the extrusion Turn off the main power supply and the main cold water valve.

(5) The safety items that the extruder should pay attention to when extruding are: electricity, heat, mechanical rotation, and the loading and unloading of bulky parts. The extruder workshop must be equipped with lifting equipment, assembling and disassembling the head, screw and other heavy parts to ensure safe production.

About

Introduction Plant Exhibition Customer CertificateProduct

Silicone Equipment Series Wire And Cable Extrusion Machine Series Silicone Extruder Series High-speed Stranding Machine Series More Products WeChat

WeChat